CARBIDE PARTS BUILT TO PERFORM

WELCOME TO ENDURANCE CARBIDE

Are your carbide wear parts performing to your application’s maximum potential? If not, you could be burning money away.

Not all parts are equal, and let us show you how better quality means higher output.

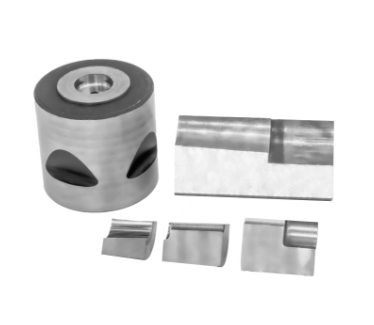

CARBIDE WEAR

PARTS

AN EXTENSIVE LIBRARY INCLUDING:

Precision wear parts designed to handle the rigors of industrial use. We’ve been providing American-made carbide solutions since 1961.

WE CREATE CUSTOM INDUSTRIAL WEAR PARTS FOR INDUSTRIES ALL OVER AMERICA

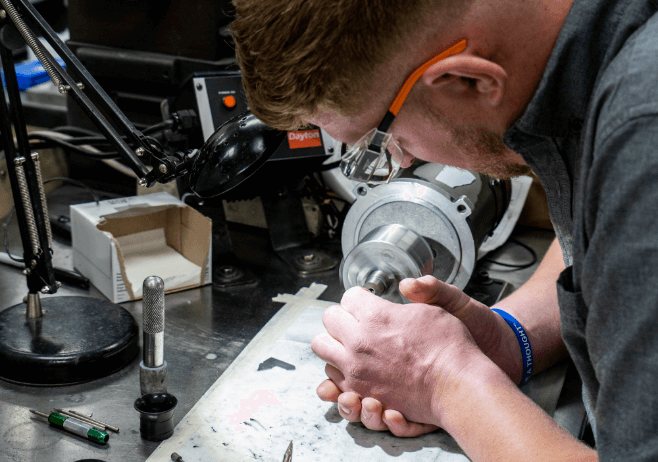

Know exactly what you need? Endurance Carbide can deliver parts exactly to your specifications. Perhaps you aren’t entirely sure what you need, but you know something isn’t working. We maybe able to lend our expertise to find the right solution for you.

BLUEPRINT SPECIALS

CONSULTATION

MILLING & TURNING

WHY PARTNER

WITH ENDURANCE CARBIDE

YOUR SATISFACTION IS OUR GUARANTEE

Our promise is simple. We will do right by you.

Let’s have a partnership worthy of a romance novel.

CERTIFIED TO YOUR

STANDARDS

ISO 9001:2015