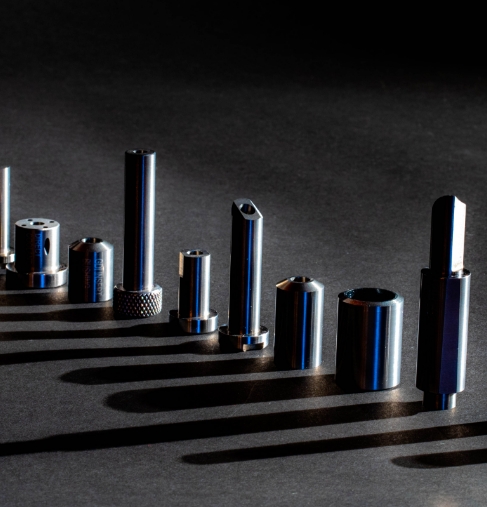

ABOUT ENDURANCE CARBIDE

SERVING CUSTOMERS WITH INTEGRITY AND PASSION SINCE 1961

Simply put, Endurance Carbide is a Michigan manufacturer of carbide wear parts including punches, dies, bushings, gages, and special “per-print” tooling. We began as a family company and still maintain our humble roots to this day.

We’ve since grown into a team of 25 employees who are committed to servicing our clients with integrity and passion for our craft. Our goals are to maximize outputs, accommodate our customers with exceptional customer service, and to always deliver on our promises! These values run deep into all of our operations, including our 100% Satisfaction Guarantee.

OUR CORE VALUES

Integrity.

Treating both our team and our customers with honesty, morality, decency and fairness.

Communication.

Keeping open and positive communication and a proper understanding of each party’s goals at all times.

Respect.

Admiration because of one’s abilities, achievements or their personal good qualities.

Commitment.

Seeing every challenge through to its solution. Keeping our promises and upholding our responsibilities.

Craftsmanship.

Producing parts and tools that we’re proud to put our name on.

OUR QUALITY POLICY

Endurance Carbide is committed to providing our customers with the highest quality products, on time…every time.

We invest in the continual improvement of our people and processes to meet applicable requirements and strive for World Class status in all we do.

Endurance Carbide takes painstaking efforts to insure delivery of quality products.

All orders are checked for accuracy when received and quality control checks are incorporated at various stages of order development, from order entry, all the way through shipment.

All of our gauges and gauging devices are routinely checked against certified masters in a controlled environment to insure and maintain accuracy at all stages of manufacturing.

Final inspection of all parts takes place in a controlled environment and all gauging can be traced to NIST standards.

Each order, every part, and all of our associates are subject to the same strict quality control procedures.