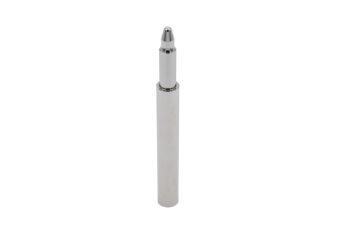

CARBIDE PUNCHES

More punching, less downtime

Carbide Punches will increase productivity by reducing replacement tooling cost and downtime. Piercing, shaving, forming, extrusion punches and burnishers per print. Specials and standards from .030″ to 4″ in diameter.

Endurance Carbide Tungsten Carbide Punches will increase productivity by reducing replacement tooling cost and downtime. Punches manufactured in carbide can improve the quality of your product and extend the life of your tooling. Working with you, to supply you with carbide components for your Die Set Assembly.

Producing a Full Range of Carbide Punches

Whatever style of punch you need, Endurance Carbide can fulfill your needs.

Endurance Carbide has experience creating carbide punches for manufacturers in:

Pilot Punch

Extrusion Punch

Pierce Punch

Straight Punch

Dimple Punch